Thorough produce knowledge for the best cutting result

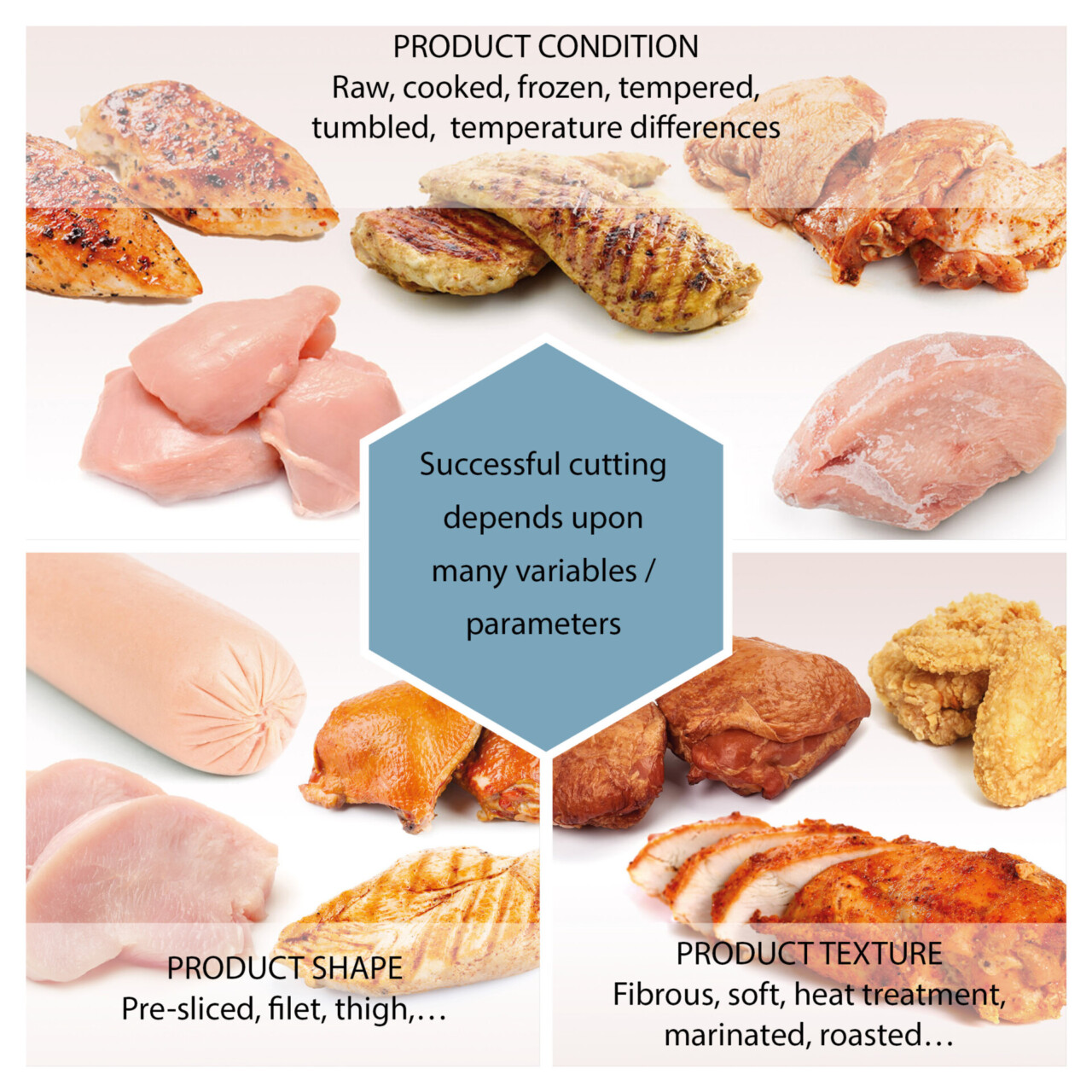

Our application specialists take pride in continuously improving their understanding of the parameters that affect the cutting of any poultry product. These include the infeed product size and shape, the temperature, texture and condition of the product before cutting.

Only then can we select the cutting solution that delivers the greatest value and best result for our customers.